How to leave an offset at the bottom of a cavity or on the lid of a punch

When we create a Roughing process on any geometry, it is easy to see how can we place an offset or stock on the walls of that geometry, but there are also times that we are interested in being able to place an offset at the bottom of the process.

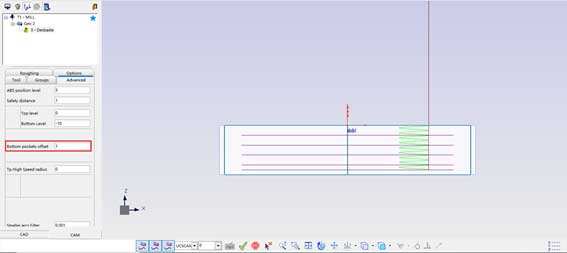

When we are entering the data in the Roughing process we have to select the tab "Advanced".

In this tab you can see that there is an option called "Lower offset" and it is here where we will place the value of the desired offset to have in the background of the geometry. This value is only applied for cavity bottoms.

If we want to leave an offset or excess on the upper part (cover) of the punches, we will use the parameter "Upper offset" where the value to be left is specified.

Apart from this parameter, we can also comment on other useful parameters of this tab:

In "Bottom Dimension" you can specify up to which Z-coordinate you want to go during the Roughing process. This allows us, independently of the Offset or Stock we want to enter, to limit the Z machining to a certain depth (for example, if the tool does not allow us to reach the bottom).

In "Upper Dimension" we can specify from which height we want the roughing to start (for example, if we have previously done other roughing and have not reached the bottom as explained in the previous paragraph).