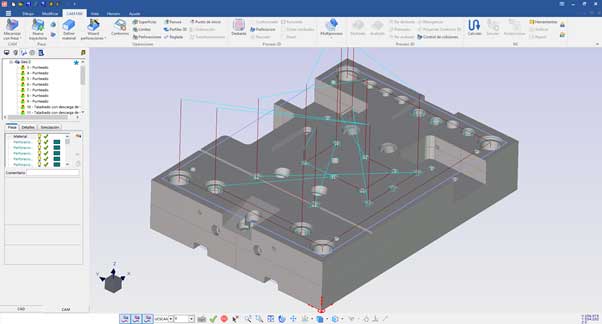

Automatic drill wizards in Fikus Visualcam

The Drill Wizard is an application with shape recognition for drilling programming, integrated in Fikus Visualcam. The Drill Wizard supports machining from 2 and 3 axes, significantly reducing in more than 80% the time required for programming.

The Drill Wizard allows you to work from both wireline and surface models, allowing you to use its full potential regardless of your usual way of working.

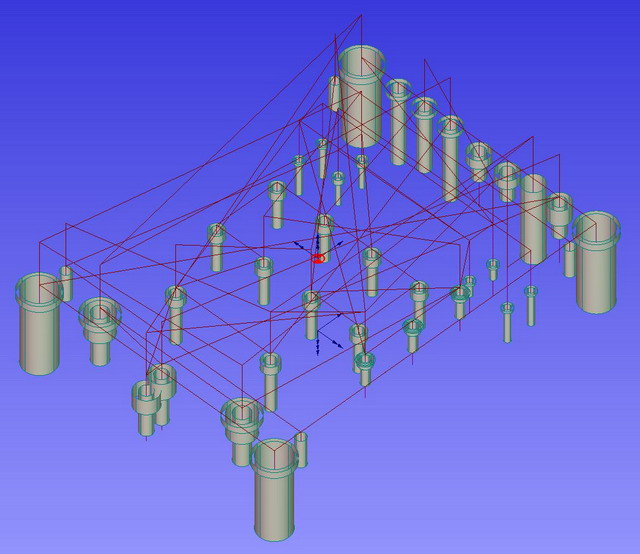

The drill wizard form show the drill families detection results, allowing user to aply the right machining strategy